A pilot plant is a pre-commercial production system that employs new production technology and/or produces small volumes of new technology-based products, mainly for the purpose of learning about the new technology.

We offer various levels of pilot skid automation from manual to fully automated, depending on need. Our in-house programming team begins developing controls while physical design is completed.

The Temperature, pressure, flow indications with historically trends on SCADA. Reports can be generated as per customer requirement.

Graphical representation of the pilot plant can be display on HMI / SCADA may in parts screen page wise depending on the size of the plant where by the status of the motors, agitators, blowers etc. can viewed on HMI / SCADA.

Recipe management needs to be incorporated in pilot plant application. Some cases, user needs to confirm the process by acknowledging / confirming the activity like pup ON, Agitator ON on SCADA / HMI to proceed further actions. This requirement typically in batch type process.

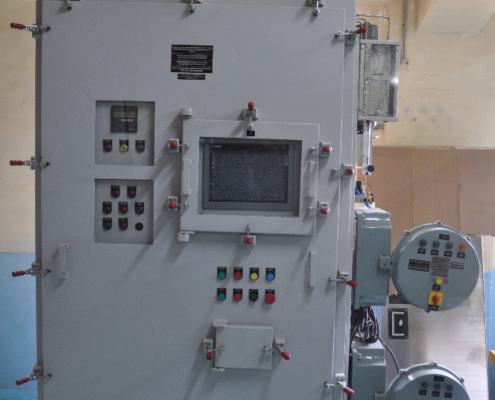

Purge type panels used in pilot plants located in hazardous areas containing flammable gases or conductive dust. The positive pressure is maintained inside the enclosure to prevent entry of the flammable gases or dust. The inside pressure is maintained in such a way that it is more than atmospheric pressure & hence prevent the outside gases enter in to the enclosure. However, in case of drop in the pressure, it will create the alarm & complete panel will be switched OFF.