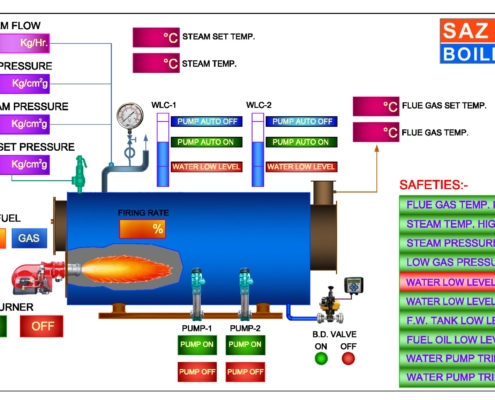

Furnace Automation

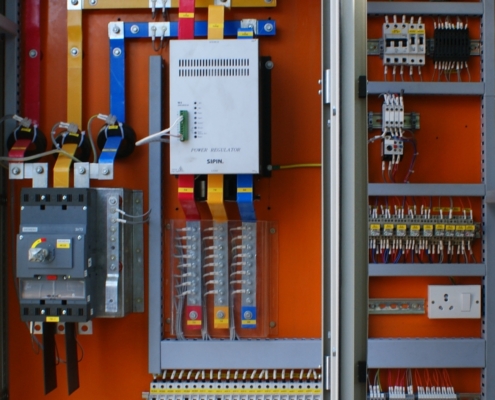

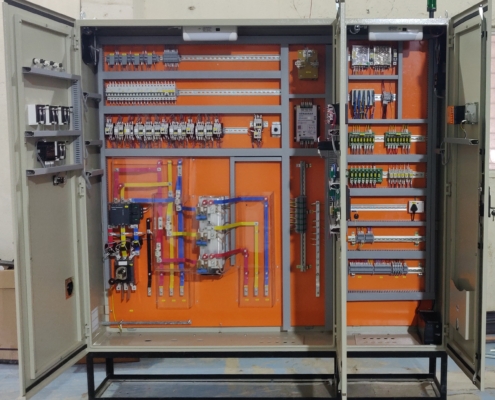

The precise controlling of the temperature in furnace like Melting, Melting cum holding & Drop bottom solution annealing furnace plays vital role. We have been using PLC / PID controllers with Thyristor controllers to control the temperature precisely in the tune of +/- 0.5 Deg. C. subject to process & heat loss. The other controls like soak time, door interlocks with heater, quenching cycle, over temperature interlocks can be done by using PLC as per the requirement of process. The rating of the heaters can be from 9 KW to 210 KW range.

The report generation for various temperatures inside the furnace can be done by using data logger OR through PLC & HMI.

The recipe can be done by using HMI for selection of components reference to variation in temperature & soak time set points.